Intelligent Pendulum

/Can you transform a 350 year old antique clock to be the most accurate in the house?

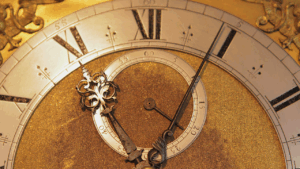

A collector with one of the world’s most comprehensive collections of early English tall case clocks came to Marble with an interesting challenge. He wanted to hear his collection chime in unison. How could we resist?

Defining the Problem

Marble identified a number of elements which contributed to erroneous changes in the amplitude and period of the swing of an antique clock and thereby effecting the absolute timekeeping. These included sliding frictions, dust accumulation, manufacturing imperfections in the clock gear teeth and train, changes in the density of the air and temperature variation effecting rod expansion. Having understood the problem the next question was how do you solve its.

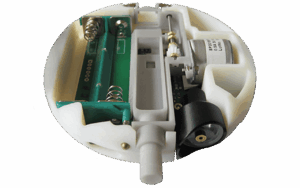

Concept generation and development

Practical experimentation and in-house development of rapid prototypes enabled real world measurements and evidence based decision making, facilitating concept selection. Appropriate technologies were tested and selected to detail into the first fully working prototype.

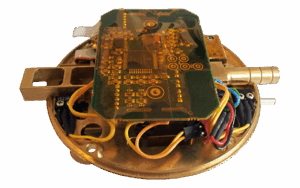

Detailed Engineering Development & Prototyping

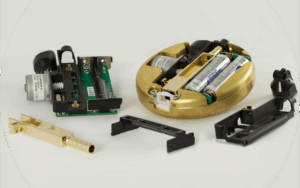

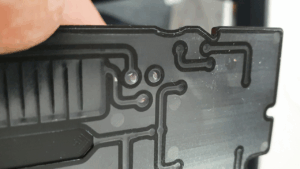

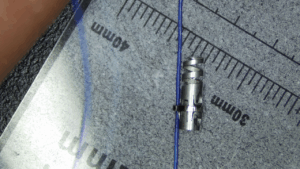

Having achieved positive results with early concept prototypes, we began detailed design and engineering of the pendulum device. This included CAD design and detailing of plastic components. Design of the rear metal casting and the formed polished brass front case. We also specified and sourced all electronic and control hardware including stepper motors and optical sensors and PCBs

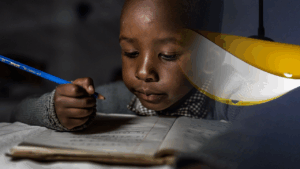

The Intelligent Pendulum enabled the clients clock collection to chime in unison. Achieving accuracy levels down to a faction of a second per day through continuous monitoring and minute micron level adjustment to the vertical position of the pendulum. This adjustment data was logged and transmitted wirelessly via IrDA to a base unit that relayed accuracy data as well as temperature, pressure and humidity direct to the cloud.

Small-Scale Production Run

Marble worked with a range of local and global suppliers to source all components before assembling 100 intelligent pendulums in our workshop in Great Shelford.