Intelligent Pendulum

Q. Can you transform this 350 year old clock to be the most accurate in the house?

A. Yes, combine some 21st century electronics and custom software with a large dose of good old fashioned physics and blend in some appealing industrial design.

The idea for the intelligent pendulum was conceived by Dr John C Taylor who has one of the world's most comprehensive collections of early English clocks. He expressed to the Marble team a simple desire 'to hear his collection chime in unison'. We set to work developing a range of concepts to substitute the pendulum bob on a long case clock with an 'intelligent' one, housing a mechanism to translate the length of the pendulum by microns. The intelligent pendulum continually monitors absolute time and adjusts its length accordingly. Product testing highlighted a huge swing in time accuracy to the antique clocks, all chiming in unison!

Elements which contributed to erroneous changes in the amplitude and period of the swing of an antique clock were identified. Sliding frictions, dust accumulation, manufacturing imperfections in the clock gear teeth and train, changes in the density of the air and temperature variation effecting rod expansion were all contributing factors, thereby effecting the absolute timekeeping. Practical experimentation and in-house development of rapid prototypes of alternative concepts enabled real world measurements and evidence based decision making, facilitating concept selection. Appropriate technologies were tested and selected to detail into the first fully working prototype.

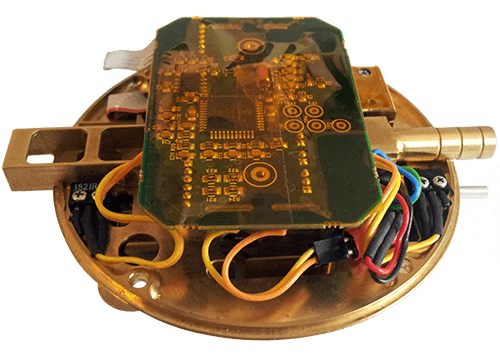

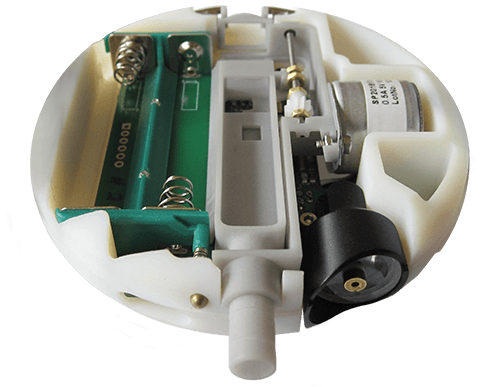

Following successful testing, the production model was developed, containing an IR transceiver, pulsed laser, accurate miniature stepper motor, temperature and pressure transducers, an accurate quartz crystal and a microprocessor. An IR communication protocol was proven in this phase to enable data to be extracted from the pendulum. Custom embedded software was written at Marble. After designing the custom PCB the team selected a low volume manufacturing partner to manufacture the PCB's. As part of the manufacturing process a test and calibration jig was designed and built to enable the automated programming of the microprocessor, 100% testing of the system and accurate time calibration.

Marble assembled the first production run in their workshops and the first sales of the intelligent pendulum were achieved from this run in 2015.

If you have a project combining mechanical engineering, industrial design, custom electronics and software, give us a call, we can help.